News / Company News

News / Company News

Yude YDIT share LED display installation and inspection precautions

Source:YDIT 誉德 Release time:2019/7/28 9:49:40 Views:1242

(LCD splicing screen, paperless conference system, ultra-thin integrated lifter) 1. LED display installation precautions

Pay attention to the following items during the installation of the LED display.

(1) The size of the frame material is determined. The size of the frame material is determined by the specification of the finished product, but it is also subject to the specification of the unit plate. When cutting the material, pay attention to the width of the aluminum alloy frame. Since the left and right are two, it is necessary to subtract twice the finished product specification when cutting the upper and lower horizontal materials. The width of the aluminum alloy frame, the left and right vertical materials should also take care of this.

(2) The corner part is connected by plastic connecting piece, and finally fixed by self-tapping screw. One corner has four screws, one on each side, and the unit board can be placed after the frame is connected.

(3) The placement of the unit board should be placed according to the specifications of the unit board. Unit boards of 4.8x0.48 size need to be placed horizontally and vertically. Place the arrows on the cell board in the same direction when placed.

(4) Tighten the special screws to the unit board, and suck all the magnetic columns. The screws near the left and right frame parts should be screwed on the row in the base of the unit board. This is convenient for fixing the side strips on the side.

(5) Install the back strip, the two ends of the back strip should be pre-punched, one end two holes, one total of four holes, fixed with the self-tapping screws and the frame material, and finally the magnetic column on the unit board is adsorbed on the back strip.

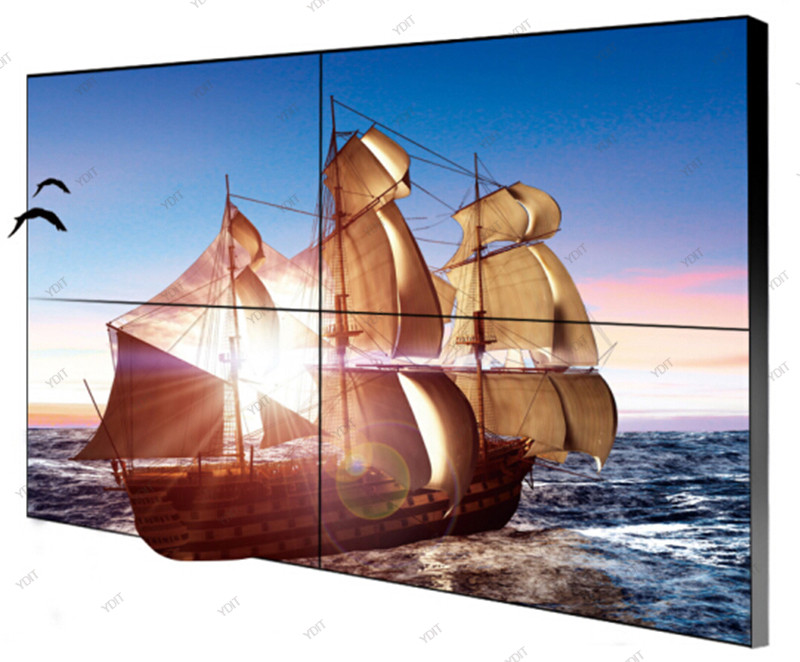

LED splicing screen

(6) Connect the unit board with the data cable. One end of the data line is inserted into the socket on the right side of the left unit board, and then the other end is connected to the socket on the left side of the adjacent unit board on the right side across the back strip, and is connected one by one.

(7) Connect the power cables between the unit boards. Connect the red line to the ACC terminal on the unit board and the black line to the GND terminal on the unit board. Connect them one by one. Be careful not to mix them.

(8) Install the power supply box and wiring. A 40A power box can be connected to a maximum of 12 unit boards, which takes into account the heat of the belt and 8 lines. There are a total of 9 terminals on the power box, from left to right: 1, 2 are the mains 20V0 interface, 3 is the ground, 4, 5, 6 are 5V positive, 7, 8, 9 is 5V negative.

(9) The number of wires of the control card should correspond to the number of rows of the cell board, but it should be noted that the OE end on the control card is colored on the side of the data cable (the cable), and the cell board is the same. Corresponding to the OE end, it cannot be reversed. Connect the RS-232 cable to the control card. In addition, the power supply on the control card should be connected to the 5V on the power supply box. It must correspond to the positive and negative poles. It must not be connected to 220V on the 1st and 2nd terminals. Otherwise, the control card will be burned out.

(10) Connect the power cable, the power cable should be connected to the 1 and 2 terminals on the power box, do not confuse, all the power boxes used must be colluded. The other end leads to a two-hole plug for power usage.

2. LED display before power-on inspection and power-on detection (liquid crystal splicing screen, paperless conference system, ultra-thin one lift)

(1) Inspection. Check that all adjacent two drive boards (excluding the fourth and fifth bars) should have a 26-core cable connection and match the 26-pin double-row pin; check that all 5V power lines are connected to the black wire. Both "COM" ends, red lines should be connected to the two "+V"; check 8 numbered 60-pin connectors and 8 corresponding motherboards should be connected.

(2) Power-on detection. Connect the AC 220V power supply. Under normal circumstances, the power indicator light is on, the control card indicator is on, and the LED display is displayed. If it is not normal, turn off the AC 220V power supply and check if the power cable and the connector are securely plugged. If the LED display is powered up normally, use the control card software to update the screen content and set the screen parameters. Send data to the LED display with a computer. (LCD splicing screen, paperless conference system, ultra-thin integrated lifter)

459496934

459496934